What are SIPs?

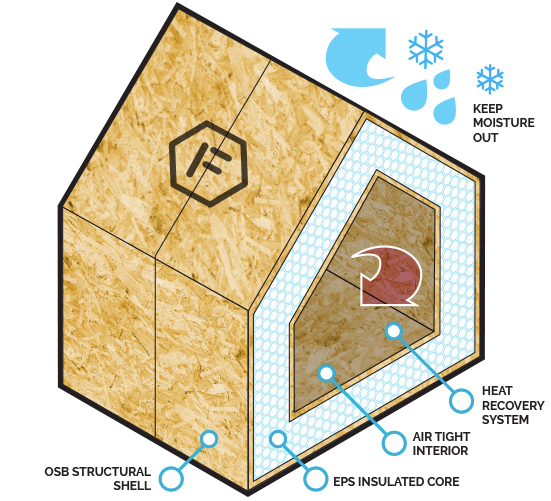

Structural Insulated Panels (SIPs, or SIP panels) are

high-performing thermally efficient composite panels that consist of a sandwich of two layers of structural board with an insulating layer of foam in between. Used as walls, roofs, and floors in residential and commercial buildings.

Formance SIPs are manufactured under factory-controlled conditions in Christchurch, New Zealand from Oriented Strand Board (OSB) and locally sourced Expanded Polystyrene (EPS). Such high levels of insulation and airtightness create the ultimate Energy Efficient home, for lower power bills and healthier living.

Superior Insulation

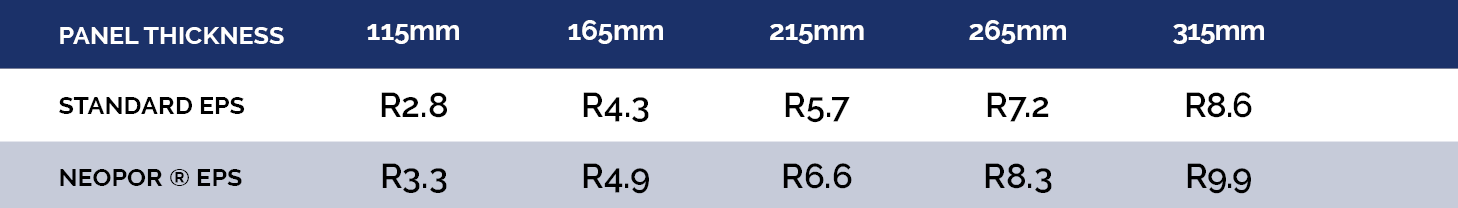

The higher the R-Value the better thermal resistance the product will provide for the lifetime of your home. Formance SIPs have superior, continuous insulation - and the true performance is through the airtightness of the envelope. There's no slumping or gaps like there is with batt insulation. Formance also offers a higher R-value product called Neopor® (graphite infused) SIPs, which with the same thicknesses, their R-value is around 18% higher than standard EPS.

Discover what homeowners Craig and Sarah think about living in a Formance home.

Build faster with Formance Prenail

SIPs can be a lot faster than traditional framing, particularly when you consider prenailed walls and roof sections.

If you're building one home or several, time is of the essence so the faster you build the sooner you can make use of the homes. Project managers will understand the time advantage of closing a home sooner, as this means work can be completed outside as well as inside the home at the same time.

Your solution to Building for Climate Change

New Zealand has committed to becoming zero-carbon by 2050, and the NZ Building Code is already beginning to align with the goal - with changes to insulation and energy-efficiency requirements already in the pipeline. Building with Formance SIPs ensure you meet the future requirements and ensure your build project is going to be a healthy home once completed.

Formance SIP homes are over 50% more energy-efficient than timber framing

Formance use OSB (Oriented Strand Board) sourced from responsibly managed forests.

Around 85%-90% of the tree wood is used to make OSB, any remaining wood (bark, saw trim & sawdust) can be converted into energy.

Our EPS is 100% recyclable, and it's the only rigid foam product that is.

Production of the EPS insulation core uses 24% less energy to make than fiberglass insulation of equivalent R-value.